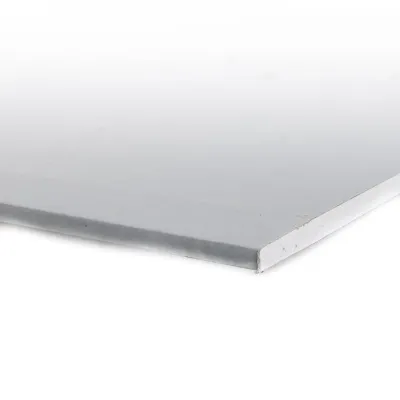

MuteBoard™ 2

Dimensions: 1200mm x 1200mm x 19mm.

Weight: 29kg

Compliance: Compliant with both Part E Building Regulations (England, Wales, Northern Ireland and the Republic of Ireland).*

Installation: Will vary depending on which system it features.

Where: Wall applications of metal, wooden, brick and concrete structures.

A two-ply acoustic board for soundproofing walls and ceilings that are perfect for rooms that have restrictions in available space, learn more about MuteBoard 2 below.

More Information

Specialist Soundproof Plasterboard for Part E Building Regulations Compliance

With nuisance noises coming from almost every direction in our urban environment, disturbing homes and workplaces, it can be challenging to find an effective solution for tightly arranged rooms.

What MuteBoard™ 2 provides you with is a slim and practical solution for the reduction of ambient noise levels that is suitable for tight, challenging spaces on both walls and ceilings. To achieve the best possible solution in soundproofing, you will need to incorporate them into acoustic systems, and these are found in our ‘Systems’ tab above, here you will find MuteBoard™ 2 in a range of options.

These offer ways of increasing acoustic performance by fitting them to decoupled stud frames, internal stud frames to split multiple rooms, or when you need to be conservative with space – directly installing them to your brick or block wall, or joist ceiling.

Information

- 1200mm x 1200mm x 19mm.

- A hand-made product that may require trimming off excess.

- For improving issues with airborne noise on both walls and ceilings.

- Application to both concrete and timber structures.

- Easy to apply a plaster skim layer directly

- Compliant with both Part E Building Regulations (England, Wales, Northern Ireland and the Republic of Ireland) and Building Standards Technical Handbook 2017 for Scotland for impact transmission.*

Whether you find that random conversation or light household use enters your home, or you are looking to put together a solution for a workplace environment that is effective and easy to install, MuteBoard™ 2 will be a great addition.

As a two-ply soundproof material, MuteBoard™ 2 comprises of a layer Tecsound SY70, and we use its self-adhesive backing to bond it to a high-density acoustic grade of soundproof plasterboard, one that is ready for skim and plastering. Both of these acoustic materials is of high value for sound control. Tecsound is a visco-elastic material that is high in mass, and mass is a crucial component in the reduction of airborne noise, and its flexible, non-rigid properties assist in decoupling from the applied surface to lessen the transfer of vibration. You will find acoustic plasterboard throughout the soundproofing world, and we incorporate this into many of our acoustic systems and products, and it is its increased mass over standard plasterboard that makes it more efficient.

MuteBoard ™ 2 is part of the MuteRange core – these products are subjected to stringent testing in both laboratory and real-world environments providing the best possible solution for the purpose with a result you can trust.

You can find out more about our all-encompassing MuteRange by clicking on the icon below if you are interested in stocking or specifying our range for projects now and in the future, get in contact with us!

FAQs

Installation Guide

You will want to make sure that the surface you are applying to is flat to avoid any joints unsuccessfully matching up. A rendering of walls will help to not only create a level wall but to patch up significant gaps in the mortar and create a stronger surface to apply MuteBoard™ 2.

When affixing MuteBoard™ 2, you will want to use heavy duty fixings with 9 per board and remember to leave a 2-5mm gap from the adjacent surfaces.

Fix MuteBoard™ 2 with tapered edge vertically.

Fill all gaps, including the abutting of all joints and around the perimeter. The aim to make sure the surface is as airtight as possible as you are trying to reduce airflow that airborne noise transfers through, even the smallest of gaps.