We work with contractors to assess the suitability of any proposed on-site works and to provide guidance and support to reduce noise and vibration at the neighbouring receptors.

Acoustic Consultants News – The Workplace Noise Regulations Explained

- February 8, 2018

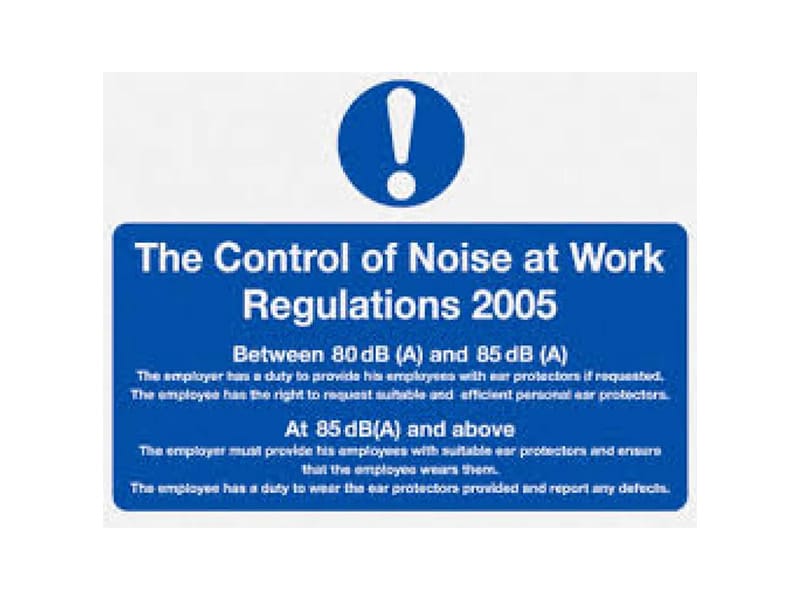

If you’re an employer working in an industry that’s notorious for the noise it produces, then one piece of legislation you might be familiar with is the Control of Noise at Work Regulations 2005.

Over one million employees continue to be exposed to harmful amounts of noise in the workplace, causing a serious risk to their hearing. Over 170,000 are reportedly currently suffering the consequences, with tinnitus, deafness, and various other conditions the result.

Let’s take a look at the act and its impact on various industries in a little more detail.

Construction noise

Construction is an industry with infamously high noise exposure levels, and lots of those employed within it can develop hearing problems. This often stems from the use of handheld equipment including chainsaws, drills, hammers, and pneumatic impact tools. Below are the decibel levels associated with a couple of widely used pieces of equipment. These levels are roughly equivalent to a loud rock concert.

• Pneumatic chip hammer – 113 decibels

• Jackhammer – 111 decibels

Understanding action levels

Construction is not the only industry associated with harmful levels of noise, but it’s probably one of the most common sources. That’s why those who work within it are probably familiar with the concept of hearing protection and action levels. For those who are not, the Control of Noise at Work Regulations impose a duty of care on employers to take precautions at set noise exposure levels. In order to assess the levels of noise employees are experiencing it is necessary to Commission a Noise at Work Survey. This is carried out by Acoustic Consultants who will measure the level of noise that employees are exposed to during an average working day or week, as well as the maximum noise (‘peak sound pressure’) that they will hear. These levels are then referenced with the three action levels below.

#1: Lower exposure Level

A workforce is exposed to lower exposure noise if the daily or weekly average within the workplace is 80 decibels, and the peak sound pressure is no higher than 135 decibels. Where this is the case, it is the employer’s responsibility to provide hearing protection, as well as be provided information and training.

#2: Upper exposure Level

You reach upper exposure categorisation once the average noise exposure in your workplace is 85 decibels or higher, and/or the peak sound pressure is 137 decibels plus. In these instances, the employer must take practical measures to bring the noise level down, by implementing engineering control or other technical measures. If this is not possible, then wearing hearing protection must be made mandatory.

Exposure limit Value

No matter what measures you take, there are also certain levels of noise that you must not exceed under any circumstances. For daily or weekly average exposure, this figure is set at 87 decibels; for peak sound pressure, it is set at 140 decibels.

How you can ensure compliance?

If you’re worried that these regulations affect you, you might be wondering what you need to do to be compliant. There are lots of steps that you can take, and the actions you adopt should be appropriate to the level of noise exposure you’re working with. That’s why we suggest you consider the following:

- Can you take action to minimise the noise your employees are exposed to? If the answer is ‘yes’, and it is reasonably practicable to do so, give it a go.

- Have you exceeded the legal limits? If so, you must find some way to reduce the noise in your workplace.

- Have you provided hearing protection? If not, why not give this a try? It’s a simple way to reduce exposure without having to change machinery or take more complicated and costly action.

- Have you established hearing protection zones? If the answer is ‘no’, read up on these and decide whether this would be a realistic option for you.

Have you ensured that your employees have access to sufficient information, instruction and training to help them reduce the risks? If not, put this in place ASAP. - Have you carried out regular health surveillance to see if employees are experiencing the effects of noise induced hearing loss?

Make sure that you know your stuff today to keep your business and your employees properly protected. Or Call NOVA Acoustics Ltd in to make light work of making your business complaint!

Recent posts

As urban areas continue to expand and human activities thrive, environmental noise pollution has become a significant concern.

Poor Sound Insulation is an issue that plagues many houses both small and large, through the development of noisy hobbies such as gaming systems, drum kits or food processors, or simply poorly soundproofed properties.